|

|

| HANDBOOK OF ENEMY AMMUNITION |

| PAMPHLET No. 8 |

| GERMAN AMMUNITION FOR GUNS AND HOWITZERS AND THE TELLERMINE |

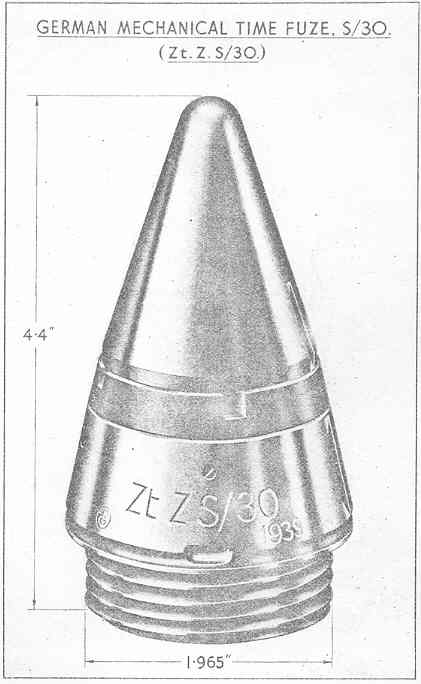

| GERMAN MECHANICAL TIME FUZE S/30 |

| (Zt.Z. S/30) |

| (Figs. 4, 5 and 6) |

| This is the standard German heavy A.A. fuze. It weighs 13 oz. 12 dr. |

|

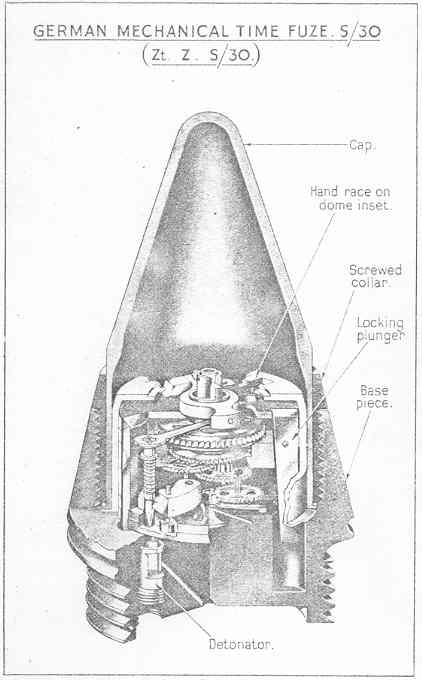

The main points of difference between this mechanical time fuze with a clock spring drive and the British No. 207 fuze are given in Pamphlet No. 6, which also includes a drawing showing the main components. The details of the mechanism, shown in Figs. 5 and 6, are as follows:– |

|

The mechanism is assembled in a cylindrical unit of superimposed brass plates and con-sists of:– |

|

The centre arbor in the form of a tubular shaft with a pinion at its base end. The upper end of the shaft is open and has two slots formed in the wall, which engage the hand centre. An external projection is formed near the base of the shaft to engage one end of the main spring. |

|

The main spring coiled under tension in a brass barrel or casing. One end of the spring engages the centre arbor whilst the other engages the casing. The cylindrical casing fits around the lower end of the centre arbor and has ratchet teeth formed around its peri-phery. These teeth are engaged by a ratchet and provide the means of revolving the case to wind the spring during the assembly of the fuze. |

|

An escapement engaging the base pinion of the central arbor comprising two spurs with pinion and a spur with the escapement wheel. The ratchet teeth of the escapement wheel are engaged by two vertical arms on the pallet, which is weighted at each end and controlled by a straight adjustable hair spring. |

|

The hand assembly carried at the upper end of the centre arbor consists of the hand centre, the hand and the hand spring. The hand centre consists of a short hollow cylin-der, open at the base, fitted with two rectangular brass arms carrying a ring near the head. The hand is of aluminium and is fixed to the ring of the hand centre. The outer end of the hand is recessed at one side to engage the spring catch on the trigger. The spiral hand spring is inserted in the open base end of hollow cylinder in the hand centre and is compressed when the hand assembly is inserted in the centre arbor and depressed to engage the rectangular arms in the slots of the arbor. The hand is retained in this posi-tion by the hand race on the dome inset and is thus prevented from rising until it has been rotated into alignment with the cut away portion of the hand race. |

| Fig. 4 |

|

|

The brass trigger, holding the outer end of the hand, consists of a brass arm pivoted at one end and stepped at the outer to engage the hand. The step is slightly undercut. A small hole in the outer side of the trigger contains a minute spring loaded plunger. The plunger is pressed into the hole by contact with the side of the slot in the top plate in which the trigger is located. A safety bridge, fitted across the slot, has a projection which overlaps the hand and thus prevents the hand rising until it has been rotated clear of the projection. This movement takes approximately one second of time. |

|

The striker, located near the circumference of the cylindrical mechanism unit, is a steel spindle with a cam collar near the lower end and a pyramid shaped point at the base. Two flats are formed at the upper end of the spindle to engage with corresponding sur-faces in the safety lever. The striker is held off the detonator by its cam collar resting on a conical headed steel pillar and on a step in the centrifugal safety catch. The spiral stri-ker spring fits over the spindle and is compressed between the cam collar and the sleeve portion of the safety lever. |

|

The safety lever is of steel and consists of a sleeve, shaped internally to fit the flat sur-faces on the spindle of the striker, and carrying an arm with an upturned end. The arm bears against the underside of the top plate and the upturned end is held adjacent to the centre arbor by the ring of the hand centre. A curved slot is cut in the top plate to permit a swinging movement of the arm. |

| Fig. 5 |

|

|

The centrifugal safety catch pivoted in the lower plate is of brass and has a step formed in one side to support the cam collar on the striker. The pivot pin is slotted to engage a coil spring which keeps the catch in the safe position. The swinging movement of the catch is limited by a steel pin fixed in the catch near the free end and a curved slot, through which the pin moves, in the lower plate. |

|

Two tapered steel locking plungers are carried in vertical slots formed down the side of the cylindrical mechanism unit. The slots are diametrically opposed and each has a hemi-spherical recess in one side to receive a corresponding projection on the side of the ta-pered plunger. The plungers are comparatively weighty and consist of steel strips taper-ing towards the base on the inner side. On the outer side of each, approximately at the centre, a projecting vertical knife edge is formed. The plungers project below the base of the mechanism unit into recesses formed in the platform of the fuze body. The recesses are sufficiently deep to permit the plungers to set back during acceleration. |

| Action |

|

The time of running is governed by the size of the arc extending counter-clockwise bet-ween the position of the hand when held by the trigger and the position of the cut away portion of the hand race. The fuze is set by turning the cap with the aid of a setting de-vice. The dome inset, with the hand race formed in its upper part, is rotated with the cap to the set position. The turning of the cap is retared by the waved wire tension spring between the screwed collar and the flange at the base of the cap. |

|

On acceleration the two tapered plungers set back into the recesses in the platform. As their wider portion with the projecting knife edge move back through the slots, the knife egde cut into the wall of the dome and thus prevent rotation of the dome relative to the mechanism. At the same time the trigger, hinging on its pivot, set back and releases the hand. The spring loaded plunger in the side of the trigger then emerges and prevents re-bound of the trigger. The release of the hand enables the main spring to rotate the cen-tre arbor, under the control of the escapement. The rotating hand, moving clear of the safety bridge, is pressed up against the hand race by the spiral spring in the hand cen-tre. |

|

During flight, the safety catch is swung clear of the striker, which is then supported only by the pillar. When the hand reaches the part of the hand race which is cut away, it is forced upwards and the ring on the hand centre moves clear of the upturned end of the safety lever. The end of the safety lever is then swung outwards by centrifugal force. The striker is turned by the lever so that the cam collar loses the support of the pillar. The spring, bearing on the cam collar, then drives the striker away from the safety lever on to the detonator. |

| Fig. 6 |

|

|

|

|