|

|

| BRITISH EXPLOSIVE ORDNANCE |

| Part 2 - Chapter 3 |

| Fuzes |

|

Tail Fuzes No. 881 Mk I and No. 883 Mk I |

| Data |

| Bombs used in | F. 8-lb. Mk II |

| Action | No. 881, long-delay and anti-disturbance; No. 883, anti-distur-bance |

| Armed condition | When safety screw is removed and arming pin withdrawn |

| Fuzes used with | None |

| Body diameter | 2.2 in. |

| Over-all length | 3.35 in. (without arming pin) |

| Color | Brass or steel |

|

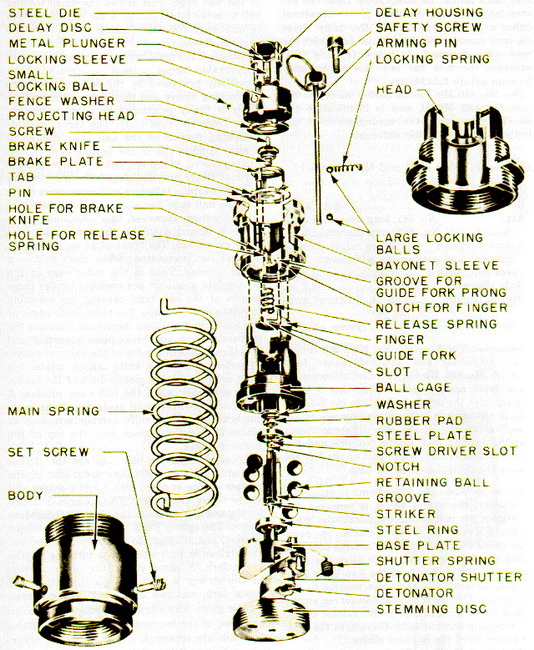

Description: The Fuze No. 881 Mk I is a combination long-delay and anti-disturbance fuze, while the No. 883 Mk I is anti-disturbance only. These fuzes are identical except that a brass plug replaces the delay assembly in the No. 883. Both are similar in external appearance to the Fuze No. 880 Mk II, the only difference being that the arming pins in the No. 881 and No. 883 are set off-center, while that of the No. 880 follows the central axis of the fuze. |

|

Operation: When the fuzed bomb is fitted into the cluster, the safety screw is remo-ved and the arming pin is linked to the parachute. When the bomb is released from the cluster, the parachute opens and withdraws the arming pin. This allows the detonator shutter to align the detonator with the striker, and the two large locking balls to move into the space vacated by the arming pin. The upper locking ball serves merely to seal the arming-pin hole. The release of the lower locking ball partially disengages the locking sleeve from the bayonet sleeve. |

|

On impac the bayonet sleeve moves downward by force of its inertia until stopped either by the main spring or by contact with the top of the ball cage. This allows the small locking ball to move into a recess in the bayonet sleeve to disengage fully the lock-ing sleeve from the bayonet sleeve. |

|

Although the main spring is assembled under considerable torque tension, rotation has been previously prevented by the ball lock between the locking sleeve and the bayonet sleeve. The latter is firmly positioned by a pin extending down from the fuze body. The three upward-extending fingers of the ball cage engage in similar notches cut in the bot-tom edge of the locking sleeve. When the locking sleeve and the bayonet sleeve are dis-engaged, the main spring exerts its toque influence and commences to rotate the ball cage and locking sleeve in a clockwise direction. However, this rotational movement is slowed down by the brake-plate and knife assembly. The brake-plate assembly consists of two perforated plastic discs held in a metal housing. Tabs in the outer edge of the brake-plate assembly are engaged by the three fingers of the ball cage, causing the as-sembly to rotate with the cage. The three knife egdes of the brake knife extend down-ward through the perforations in the brake-plate assembly and into three holes in the top of the bayonet sleeve. Therefore, the brake knife cannot rotate, but must cut through the plastic discs of the brake-plate assembly when the ball cage rotates. A small screw with a long projecting head holds the brake-plate and knife assembly loosely in place. This screw threads into the top of the bayonet sleeve. |

|

Loacted inside the ball cage are the striker and six retaining balls. The lower end of the release spring is fitted into a screw-driver slot in the top of the striker. The upper end of this spring engages a hole in the base of the bayonet sleeve. The spring itself is loaded under torque tension, and attempts to rotate the striker, but the striker is pre-vented from rotating by the guide fork. A notch cut in the upper portion of the striker is engaged in a slot cut in the guide fork, and two upward-extending prongs on the guide fork engage in similar grooves in the base of the bayonet sleeve. The six retaining bals are arranged, one on top of the other, in two layers of three balls each. In the unarmed position, these balls are held in place around the striker by the inner walls of the ball cage. The ball cage is prevented from rotating more than 60°, since the fingers of the cage come up against the ends of the slots in the base of the bayonet sleeve at the end of that distance. Rotation of the ball cage through 60°, however, present cut-away por-tions of the inner walls to the balls. The balls are then prevented from scattering only by point contact between themselves, the steel ring placed around the striker above their, and the steel plate placed around the striker below the balls. When the ball cage has completed its 60° rotation, the fuze is fully armed. |

|

A delay assembly in the top of the fuze consists of a housing containing a metal plun-ger and a plastic delay disc. When the bayonet sleeve is disengaged from the locking sleeve, the main spring forces the bayonet sleeve upwards, bringing the extended por-tion of the screw into contact with the plunger, which gradually forces its way through the delay disc. When the bayonet sleeve has risen sufficiently to disengage the prongs of the guide fork, the striker is allowed to rotate under the torque tension of the release spring. The flick motion imparted to the striker scatters the balls and allows the striker to be forced into the detonator by the main spring working through the ball cage. |

|

Disturbance of the fuze prior to its long-delay functioning will scatter the balls from under the striker and the ball cage, under the compression of the main spring, will move downward, bringing the striker into contact with the detonator. |

|

|

|

Figure 174 - Tail Fuze No. 881 Mk I |

|

| Figure 175 – Exploded view of Tail Fuze No. 881 Mk I |