|

|

| Fuzes for Rockets and Projector Charge |

| Chapter 4 |

| NOSE FUZES FOR 7.2-INCH CHEMICAL ROCKET |

| Section A - Nose Fuze Mk 147 Mods 0 and 1 (Setback and Air Arming, Impact Firing) |

| 1. General Data |

|

Used in: 7.2-inch Rocket Head Mk 7 (Chemical or Smoke) |

|

Overall dimensions and weight of fuze: |

|

Length |

16.1 inches (Mod 0) |

| 16.2 inches (Mod 1) | |

|

Diameter (maximum) |

1.750 inches |

|

Body threads |

1.500 inches – 12 NF - 2 RH |

|

Weight |

1.30 lbs. approx. |

|

Applicable specification: OS 3579 |

|

General arrangement drawing: |

|

304940 (Mod 0) |

|

423842 (Mod 1) |

|

Sketch list of drawnings & specs: |

|

109548 (Mod 0) |

|

109372 (Mod 1) |

|

Explosive components: |

|

A sensitive stab type compound detonator Mk 23 Mod 0 (lead azide primer mixture, lead azide, and tetryl) |

|

Burster lead-in charge (tetryl) |

|

Burster charge (tetryl 65 grams approximately) |

| 2. Description |

|

General. Fuze Mk 147 Mod 0 or Mod 1 is a nose fuze designed for 7.2-inch chemical rockets. The fuze is setback and air-arming, impact firing. It functions instantaneously upon impact with a suitable target. |

|

Fuze Mk 147 Mod 0 is fitted with a fixed cylindrical guard which protects the propeller from damage. The propeller vanes are bent to an angle of 70°. Fuze Mk 147 Mod 1 has a detachable shipping cap which protects the propeller from damage during shipping and the fuze from weather. Since the air stream is more effective on the Fuze Mk 147 Mod 1, the vanes are bent to an angle of 78° to keep the arming distance the same as for the Fuze Mk 147 Mod 0. The shipping cap on the Fuze Mk 147 Mod 1 is removed as the rock-et is loaded on the launcher. |

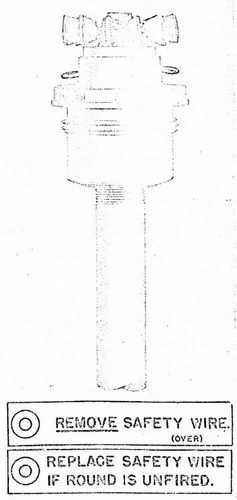

| Figure 18 – Nose Fuze Mk

147 Mod 1, External View with Guard Removed, Full Size (approximately) except for Burster Tube Length |

|

|

Use. Fuze Mk 147 Mod 0 or Mk 147 Mod 1 is used in the 7.2-inch Rocket Head Mk 7 when assembled with the 3.2-inch Rocket Motor Mk 5. The complete round is fin stabili-zed and surface launched for use in dispersing chemical or smoke agents. It has a maxi-mum range of approximately 3,400 yards. |

|

Functioning mechanism. Fuze Mk 147 consists of a brass fuze body which provides housing for the threaded firing pin, the setback collar with propeller locking pin, the set-back spring, the firing pin guide, the spacing sleeve, the shutter with the detonator and locking detent, the lead-in disc with lead-in charge, and the burster adapter with exter-nal burster tube and charge. The propeller and its hub are mounted externally at the for-ward end of the threaded firing pin and are secured in position by means of a cotter pin. |

|

The forward section of the fuze body is tapered slightly towards a nose surface. Be-low the tapered section the body diameter increases to serve as a mounting support for the vane guard in Fuze Mk 147 Mod 0 and as a shoulder for the external installation threads. A deep bore with counterbore provides the internal housing for the fuze ele-ments. The thin nose wall is drilled and threaded at the center with light shear threads, and a second hole is drilled off center to accommodate the propeller locking pin. The counterbore at the base of the fuze is threaded to engage the burster adapter. |

|

The propeller assembly consisting of the propeller and hub is secured to the firing pin. Below the hub the firing pin is threaded for a short distance and these threads engage the threaded hole in the nose of the fuze body. A shoulder on the firing pin below the threads tapers rearward to form a conical surface which is followed by an elongated sec-tion at its end to a sharp point. The shoulder prevents the retraction of the firing pin be-yond the threads during arming and the conical surface acts as a stop to control the depth of penetration of the firing pin on impact. The setback block, a steel inertia block with an integral propeller locking pin, floats around the firing pin on the setback spring and bears against the nose wall. The propeller locking pin extends from the forward sur-face of the setback block through the guide hole in the nose wall to engage a river or embossed stop in the propeller hub which locks the propeller assembly. The setback spring at its forward end bears against the setback collar and at its base against the firing pin guide. The firing pin guide, a flat steel disc with the center portion raised to align the setback spring and drilled to accept the pointed shaft of the firing pin bears against the shoulder provided by the counterbore. The firing pin guide has a hole drilled in its base which receives the shutter hinge pin. The modified semi-circular shutter hou-ses the detonator and pivots by means of the shutter hinge pin under the force of a tor-que spring after the firing pin has been retracted. A small spring loaded detent in the shutter engages a small well in the firing pin guide after arming. A ring type sleeve bears against the firing pin guide and positions the lead-in disc with its charge. The burster tube and burster adapter are installed into the base of the fuze body and bear against the lead-in disc separated by the thin paper booster disc. With Fuze Mk 147 Mod 0 a re-movable safety locking wire clips over the propeller guard and passes through aligned holes in the fuze body and also engages a slot in the setback block to lock the setback block and propeller locking pin in forward position. With Fuze Mk 147 Mod 1 the propeller guard is replaced by a removable cap type guard, and the safety locking wire passes through aligned holes in the fuze body and setback block in the same manner as indica-ted above. |

|

Figure

19 – Nose Fuze Mk 147 Mod 1, Cross Section View, |

|

|

| 3. Functioning |

|

Arming. After the rocket has been loaded into the launcher, the shipping cap (in Fuze Mk 147 Mod 1 only) and safety wire are removed. When the rocket is fired, the set-back force, due to the acceleration of the round acting on the setback block, forces the block back, compressing the setback spring. This movement withdraws the propeller locking pin from engagement with the hub. The air stream acting on the propeller as-sembly causes it to rotate and unscrew the firing pin from the fuze body. The setback force acts on the setback block only during burning of the rocket motor, after which the setback spring returns the block to its original forward position. However, the firing pin has meanwhile unscrewed from the fuze body sufficiently to prevent re-engagement of the propeller locking pin with the propeller. The propeller is so adjusted that under the least faverable conditions (short burning distance at maximum service temperature) the firing pin assembly makes the required two complete turns during acceleration of the rocket to advance the firing pin sufficiently to prevent re-engagement of the propeller locking pin with the stops on the hub before the end of burning of the rocket. |

|

Rotation of the propeller continues to unscrew the firing pin, until an unthreaded sec-tion is reached and a shoulder on the pin comes up against the top of the fuze body, after which the firing pin assembly rotats freely. Before the firing pin is unscrewed it holds the detonator shutter to one side, so that the detonator is out of alignment with the firing pin and booster lead-in. When the firing pin unscrews, the shutter is released, and the shutter spring rotates the shutter against a stop pin. A shutter detent engages a hole in the firing pin guide and locks the shutter in position. The detonator is now alig-ned with the firing pin and the booster lead-in, and the fuze is fully armed. |

|

The arming distance for Fuze Mk 147 used in the 7.2-inch chemical warfare rocket is about 200 feet. |

|

Firing. On impact, the firing pin is forced back to shear the light screw threads in the nose wall of the fuze body and to pierce and fire the detonator which in turn fires the lead-in charge and the burster charge. |

|

Acceptance test data. Sample fuzes chosen at random from each production lot are subjected to routine ballistic test when fired in rocket ammunition in accordnance with the following procedure: Completely loaded fuzes from each lot shall be installed in "FS" smoke loaded 7.2-inch Rocket Heads Mk 7 with live loaded motors and fired for function-ing. Half of the rockets shall be fired for water impact and the other half for ground im-pact. All fuzes shall be fired at an angle of elevation of approximately 45 degrees. Ninety percent high order functioning shall be considered acceptable. Any prematures shall be causes for rejection of the lot. |

|

Sensitivity limits. This fuze will fire reliably on water and ground impact, except at small angles of impact. The minimum angle of impact on soft ground for consistent firing is 15 degrees. |

| 4. Safety Features |

|

Detonator safety. Fuze Mk 147 is detonator safe. In the unarmed position the deto-nator is out of alignment with the explosive train. Should the detonator function prema-turely, the force of the detonator will be dissipated forward through a hole in the firing pin guide and away from the explosive components. When the fuze is installed in a rocket head, it is locked in the unarmed position by the propeller locking pin. The fuze is not ar-med until the setback force withdraws the propeller locking pin, and the propeller rotates and unscrews the firing pin to a point where the detonator shutter is released. |

|

During shipping and stowage. Sample fuzes from production are subjected to rough handling tests which are considered to be more severe than conditions encountered in normal stowage and shipping. Failure to pass these tests is cause for rejection of the lot. Additional safety is provided during shipping, stowage, and until the rocket is loaded into the launcher, by use of a safety wire. The wire passing through the fuze body locks the setback block in forward position so that the propeller locking pin engages and locks the hub. The guard or cap protects the propeller from damage during normal conditions en-countered in stowage and handling. |

| 5. Disposal and Servicing (Maintenance) |

|

General. If the fuze is accidentally armed, whether assembled in the rocket head or not, no attempt should be made to unarm it. The fuze shall be considered armed if the propellers is out of engagement with the propeller locking pin so that the propeller is free to rotate. If the fuze is armed, turning the arming vane counterclockwise as viewed from the nose will cause the firing pin to pierce the detonator and initiate the burster. Re-placing the safety wire will not render an armed or partially armed fuze safe. The safety wire merely locks the setback block and propeller locking pin, and if the latter does not engage the propeller, the safety wire serves no purpose. Armed fuzes must not be fired from rocket launchers. If the fuze in an assembled round is armed accident-ally, the propeller should be carefully taped to prevent further rotation, and the fuze then carefully removed from the rocket taking care not to drop the round or the fuze on its nose or in any way strike the fuze. Dud rounds should be threated with extreme caut-ion. If the propeller is bent or driven flush with the nose of the fuze body, the fuze is in a fired condition. In such a condition, the firing pin or propeller should not be disturbed, as the firing pin may be imbedded in the detonator and any movement may create sufficient friction to inititiate the sensitive detonator. The fuze or fuzed round should be disposed of by gently lowering into deep water or by Explosive Ordnance Disposal Personnel in ac-cordance with existing instructions. |

|

Disassembly. Disassembly of this fuze is not permitted except at authorized activi-ties when directed by the Bureau of Ordnance. |

| 6. Installation Instructions |

|

1. Remove the dummy nose plug from the rocket head and inspect the liner and clean if neccessary. |

|

2. Remove the fuze from the container and examine to see that the gasket is present and the fuze is not damaged. If defective, repack, seal, and return to an ammunition depot. |

|

3. Screw the fuze with gasket securely into the nose of the rocket head, using the proper fuze spanner wrench. |

|

4. After placing the rounds on the launcher, remove the guard (applicable for Fuze Mk 147 Mod 1) and the safety wire. In some launchers this is not possible. For these the safety wire and shipping guard should be removed immediately before loading the round. Do not discard the safety wires until the rounds are fired. |

|

Removal from round. Should it become nessessary to remove the rocket from the launcher, the safety wire and shipping guard should, if possible, be replaced first. The fuze may then be removed from the rocket head with proper fuze spanner wrench and returned to its shipping container. The closed shipping can should be sealed with adhes-ive tape along the broken surface. The shipping plug must be replaced in the rocket head after the fuze is removed. |

| 7. Packing and Marking. |

|

Packing. Fuze are individually packed into hermetically sealed cans. Twenty-four fuz-es are packed into a box 23.3 inches by 15.0 inches by 18.1 inches which represents a total of 3.6 cubic feet and a total weight of 89 pounds. |

|

Marking. The fuze is marked or stamped with the letters NF, the mark, the mod, and the lot number, the manufacturer's initials or symbol, the initials or symbol of the loading facility, the month and year of loading, the anchor stamp, and the inspector's initials. |