|

|

| HANDBOOK OF ENEMY AMMUNITION |

| PAMPHLET No. 9 |

| GERMAN TELLERMINES, DEMOLITION CHARGES, FUZES AND GUN AMMUNITION OF CZECH ORIGIN, ITALIAN FUZE, PRIMER AND SHELL |

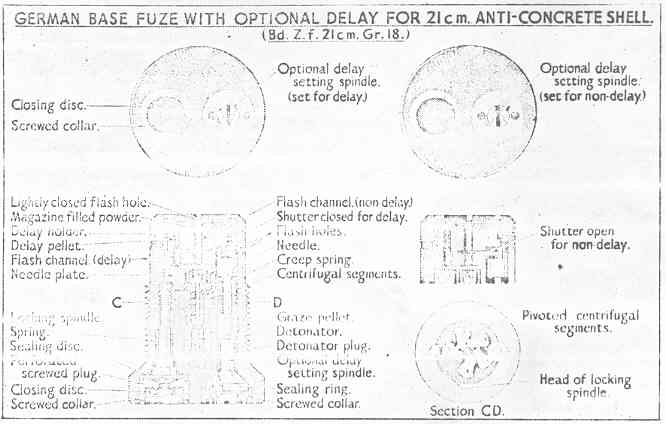

| GERMAN BASE FUZE WITH OPTIONAL AND VARIABLE DELAY FOR 21 CM ANTI-CONCRETE SHELL |

| (Bd.Z. f. 21 cm Gr. 18 Be.) |

| (Fig 7) |

|

The fuze is of the igniferous type and is used with a gaine in the anti-concrete shell (Gr. 18 Be) for the 21 cm heavy howitzer (Mrs. 18). The shell is described in Pamphlet No. 8. The designation of the fuze "Bd.Z. f. 21 cm Gr. 18 Be", is stamped in the base of the fuze where there is also a setting device for optional delay. The setting index is in the front of an arrow head which is set to a graduation marked "MV" for delay or to a gra-duation mark "OV" for nondelay. |

|

The graze mechanism consists of a fixed needle and an inertia pellet carrying the deto-nator with a creep spring inserted between the needle holder and the pellet. The needle holder is in the form of a disc with flash channels, the needle being secured by a scre-wed plug. |

|

A safety device consisting of five pivoted centrifugally operated segments is fitted at the top of the pellet recess. The segments are shaped to interlock and, instead of being re-tained in the safe position by the usual expanding spring ring, the releasing segment is held by a locking spindle. The spindle is contained in a longitudinal recess displaced from the centre of the fuze and has a head formed on its inner end to engage the segment. The spindle is retained in this position by a spiral spring. The base of the spindle is of larger diameter for operation by the pressure of gases from the propellant charge and is covered by a copper sealing disc to prevent the gases entering the fuze. The copper sealing disc is secured by a perforated screwed plug and the recess is closed at the base by a foil disc secured by a screwed ring. |

|

The optional delay device consists of a centrifugally operated shutter which is prevented from moving clear of the open flash channel in the delay unit by the setting spindle when set for delay. The shutter is carried on a platform fitted above the needle holder and is of the sliding type. The platform is recessed on the underside to form a cavity with two flash channels; one leading to the open channel in the delay unit and the other, fitted with a sealing tube, to the delay channel. The setting spiral is contained in a second longitudinal recess, diametrically opposite to that containing the locking spindle, and has a portion of the head cut away to provide clearance for the slinding shutter when the spindle is set to the "OV" (non-delay) graduation on the base of the fuze. The spindle is coned near the base to correspond with a coned seating in the body so as to provide a seal against gas pressure and has a slot in the base for the setting key. A screwed collar in the base of the fuze retains the spindle in its recess. A sealing washer of lead is held in circular grooves between the collar and the spindle. |

|

The delay unit is shaped at the base to fit over the shutter and has two longitudinal channels. One channel is central, contains no filling, and leads direct to the magazine. The other channel is displaced from the centre and contains a pressed filling of delay composition. This channel leads to the outer edge of the magazine. |

|

The magazine contains pressed gunpowder and is closed by a screwed plug with a cen-tral flash hole. The hole is closed on the inside by a paper disc. |

|

| Action |

|

Before loading, the fuze is set for delay or non-delay by rotating the setting spindle so that the arrow head at its base is aligned with the "MV" or "OV" graduation respectively. |

|

During the travel up the bore the propellant gases destroy the foil disc and passing through the perforated plug, press the copper sealing disc and the locking spindle for-ward. The head of the locking spindle is thus moved clear of the segment which is free to move. The entry of the gases into the fuze is prevented by the copper sealing disc, the coned portion of the setting spindle and the lead washer being pressed into their seatings. |

|

During flight, the tendency of the graze or inertia pellet to move forward as the result of deceleration is prevented by the creep spring. Also, the centrifugal segments are rota-ted, in succession, clear of the path of the pellet by centrifugal force. With the setting spindle set to "OV" (non-delay) the shutter is also thrown outwards, leaving the direct flash channel to the magazine open. |

|

On graze, the momentum of the pellet overcomes the creep spring and the detonator is impinged on the needle. The flash passes through the channels in the needle holder and enters the magazine via the central channels in the platform and the delay unit. |

|

With the setting spindle set to "MV" (with delay) the head of the spindle prevents the shutter from moving clear of the central direct flash channel. The flash can then reach the magazine only by the channel containing the delay composition. |

|

|