|

|

| HANDBOOK OF ENEMY AMMUNITION |

| PAMPHLET No. 8 |

| GERMAN AMMUNITION FOR GUNS AND HOWITZERS AND THE TELLERMINE |

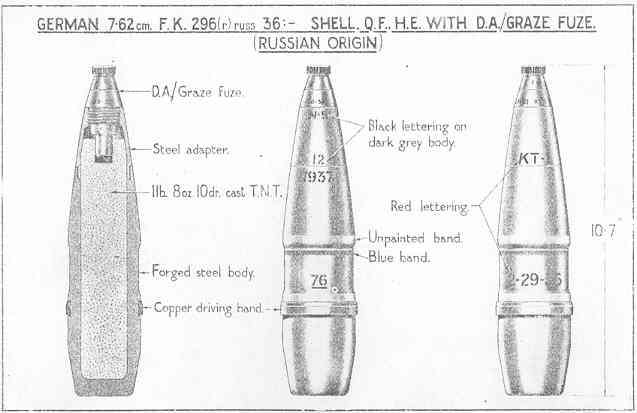

| GERMAN 7.62 cm CARTRIDGE, Q.F., H.E. RUSSIAN ORIGIN |

| (Sprgr.Patr. 280 (r) - russ 354 M (Tp)) |

| (Figs. 18 and 19) |

|

This fixed Q.F. Russian ammunition is used by the Germans in the 7.62 cm F.K. 296 (r) russ 36, a light Russian field gun. The shell is painted a dark grey and stencilled in black and red. In some instances a blue band is painted round the shell below the shoulder. The nose fuze is of steel and is fitted with a screwed cap. Stencilling in black on the side of the case includes the abbreviated designation of the equipment in the form "7,62 CM FK 296 (r) – russ 36 –". The normal charge temperature on which the weight of the pro-pellant charge is based is indi-cated by the marking "P.T. + 25° C" in red near the base of the case. The marking "Sprgr", indicating the nature of the shell, appears in white paint on the base of the case. The overall length of the round is approximately 25.7 in-ches and the weight 19.4 lb. |

| The complete round consists of the following components:– |

|

Shell filled T.N.T. |

|

Brass cartridge case. |

|

Propellant charge of nitrocellulose powder. |

|

Percussion primer. |

|

Combined direct action and graze fuze. |

| Shell (Fig. 18) |

|

The streamlined shell is of forged steel with a band formed below the shoulder and anot-her above the driving band. These bands are not painted. The driving band is wholly of copper. A nose adapter of steel is screwed into the head of the shell. The adapter is shaped to coincide with the contour of the head and is screwthreaded internally to re-ceive the fuze. The weight of the empty shell with the adapter is 11.3 lb. |

|

The bursting charge consists of approximately 1 lb. 8 oz. of cast T.N.T. with a cavity at the top to receive the magazine of the fuze. The T.N.T. corresponds to the "Grade I" used in the British service. |

|

| Case |

|

The brass cartridge is 15.1 inches in length and is mot necked. The primer hole in the base is 0.99 inches in diameter and has 14 screwthreads to the inch. The flash-hole at the inner end of the primer boss is closed by a cloth disc which is shellacked in position. |

| Propellant Charge |

|

The propellant charge consists of 2 lb. 4 oz. 9 dr. of nitrocellulose powder in the form of short multi-tubular grains. The grains average 0.477 inches in length and 0.231 inches in diameter and have 7 pervorations. The mean web thickness is 0.042 inches. |

|

The propellant is apparently of American manufacture, the composition as found by ana-lysis being:– 95.83 per cent of nitrocellulose (nitrogen content 13.21 per cent), 0.89 per cent of diphenylamine, 0.3 per cent of nitroso diphenylamine and 2.98 per cent of volatile matter. |

| Primer |

| The percussion primer is of the type described in Pamphlet No. 6, page 19. |

| Fuze (Fig. 19) |

|

The steel body of the fuze has an aluminium screwed in at the base and a central recess which contains the graze arrangement. The recess has a flash-hole in the base leading to the magazine and is screwthreaded at the forward end to receive the steel head of the fuze. |

|

The brass graze pellet carries a 1.9 grain igniferous detonator at the head and has a spi-got at the base which seats in the flash-hole leading to the magazine. A copper washer, fitted to the base of the pellet, in conjunction with the spigot provides a seal against the flash from the detonator if initiated prematurely. A central recess is formed in the pellet, apparently for adjustment of the weight and possibly as a trap for debris from the deto-nator. The head of the pellet is flanged to engage the inner arms of the retaining spring. |

|

The brass retaining spring is fitted over the head of the graze pellet and is in the form of a capsule with a perforation in the head to coincide with the detonator, four sprung inner arms to engage the flanged head of the pellet and four similar outer arms which engage the arming sleeve. |

|

The brass arming sleeve fits over the retaining spring and, by engaging the outer arms of the spring, holds the graze pellet in the base of its recess. Forward movement of the sleeve is prevented by the base end of the fuze head. The sleeve is in the form of a hol-low cylinder with an internal groove to engage the outer arms of the retaining spring when armed and an external flange at the head to engage the arming spring. The other end of the spiral arming spring is supported by a step formed in the body recess. |

|

The steel head of the fuze is recessed at the nose to accommodate the striker assembly and at the base to permit the forward movement of the graze pellet on functioning. The diaphragm between the two recesses is drilled for the needle of the striker and stepped to form a support for the striker spring. An external screwthread is formed at the nose to receive the steel cap. |

|

A brass check ring with four internal projections is fitted in the base recess of the head to prevent the graze pellet carrying the detonator forward on to the striker during flight. The check ring is secured by a retaining ring screwed into the mouth of the recess. |

|

The striker assembly consists of a steel needle with a holder at the head, which supports a wooden hammer, and a spiral spring held between the holder and and the diaphragm. The recess containing the striker assembly is closed against air pressure by a brass wind shield. |

|

The magazine filling is designed to function as a gaine and consists of 127 grains of C.E. with a detonator at the head. The detonator is embedded in the C.E. filling and contains 2.8 grains of lead azide with 0.5 grains of lead azide/styphnate above and 1.9 grains of C.E. below. The detonator filling is covered by a perforated capsule and a gauze disc. The detonator shell is closed at the mouth by a brass perforated ferrule which is fitted in an arrangement of paper and millboard washers and the steel washer closing the head of the magazine. |

|

|

| Action |

| For graze the cap remains on the fuze. |

|

On accelaration the arming sleeve sets back over the retaining spring and compresses the arming spring. In this position the outer arms of the retaining spring engage in the internal groove in the sleeve and retain the sleeve in this position relative to the graze pellet. During deceleration the compressed arming spring pushes the sleeve forward, tak-ing with it the graze pellet until the pellet is stopped by the projections on the check ring. On graze the momentum of the pellet overcomes the resistance of the check ring and carries the detonator on to the needle. The flash produced by the igniferous deto-nator passes to the detonator in the magazine, which brings about the detonation of the C.E. filling. |

|

For direct action the cap is removed before loading so that in addition to the graze pellet moving forward, the needle is driven in on impact. |

|

|