| HANDBOOK OF ENEMY AMMUNITION |

| PAMPHLET No. 3 |

| GERMAN AND ITALIEN AMMUNITION |

| GERMAN 2-KG ANTI-PERSONNEL AIRCRAFT BOMB ("BUTTERFLY BOMB") |

|

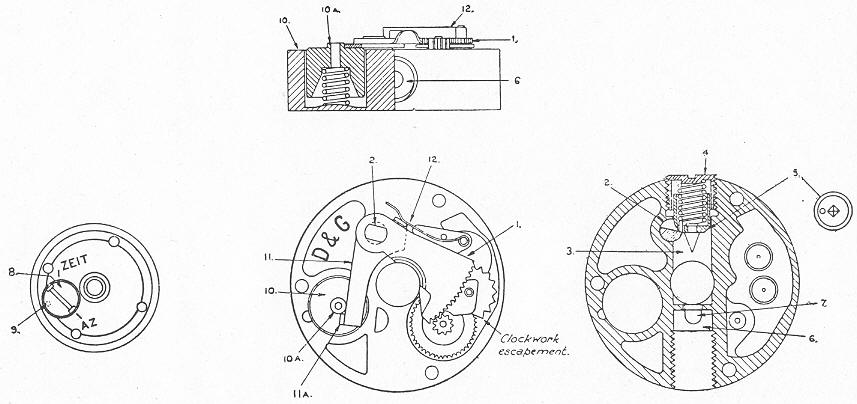

(Figs. 26 and 26a) |

|

This H.E. bomb, fitted with a mechanical fuze which has an alternative time or percussion action, makes use of a hinged outer casing to arm the fuze during its fall. The time ac-tion of the fuze is not varible, so that when the time of arming and running exceeds the time of flight the effect of a delay fuze is produced, i.e., a short period will elapse after impact before detonation occurs. |

|

|

|

Fig. 26 |

|

The bomb body is a cast-iron cylinder (D) 3 inches in diameter and 3.1 inches long, the average wall thickness being about 3/8 inch. A screw-threaded fuze hole is provided in the side of the body. The interior is coated with a bitumen composition and contains a bursting charge consisting of 7½ oz. of cast T.N.T. topped with the bitumen composition and designed to form an exploder cavity. |

|

The outer casing is of steel and encloses the bomb. The casing consists of two half cy-linders connected by hinging at on side and by a securing pin passing through two lugs on the other side. Carried at each end of the hinge bar is a hinged disc. These disc form the end pieces of the cylindrical casing and are positioned by internal flanges formed at the ends of the half cylinders. The hinges of the disc are inclined in such a way that the discs in the open position are set a pitch similar to that of an arming vane. Springs are fitted to the discs and half cylinders which cause them to open on their hinges when the safety pin is removed. The outer casing is connected to the lead of the safety bolt of the fuze (C) by a short length of steel cable (B). The cable is fitted with a steel head (A) for attachment to the outer casing. |

|

|

|

Fig. 26a. |

| Fuze |

|

(Fig. 27) |

|

The fuze consists of three main parts, the cap (E), the body (F) and the base ring (K). The cap and body appear to be made of diecast alloy – probably zinc base – and the base ring of aluminium alloy. The three portions are bolted together by 3 bolts. |

|

|

Fig. 27 |

|

The cap, which is cylindrical, is fixed to the upper side of the body and is screw-threa-ded for insertion into the bomb. On the underside it is recessed to house the mechanical portions fitted on the body and a central hole at the top is provided with a screw-threa-ded bush to receive the safety bolt. On the upper side of the cap a setting plug (8) is provided by means of which percussion or time action can be arranged. The cap is en-graved with two index lines, one marked "AZ" (Aufschlag Zunder, i.e., impact fuze) with which the slot in the setting plug is aligned for percussion actin and the other marked "ZEIT" (Time) which is the setting mark for time action. Beneath the setting plug is posi-tioned a small pin (9) which is moved in towards the body when the plug is set to "ZEIT" and withdrawn when set to "AZ". |

|

The safety bolt is connected at its outer end to the connecting cable of the outer cas-ing. The bolt is provided with a double thread for a portion of its length to engage the bush in the cap and is provided with a collar at its inner end which limits the extent to which the bolt can be withdrawn. When screwed home the safety bolt prevents the ope-ration of the clockwork mechanism and masks the detonator (6) from the striker (5). |

|

The body, which is also cylindrical in shape, carries the striker and detonator assemblies in a lateral channel (3). Communicating with this channel is a vertical channel in the cen-tre of the body to receive the safety bolt and a small vertical channel (7) adjacent to the detonator which leads to the gaine. A semicircular recess is formed in one side of the lateral channel to house the retaining shaft (2). The striker assembly consists of a spiral spring (which also provides the motive power for the clockwork mechanism) held under compression between an outer sleeve screw-threaded for assembly in the body and an inner sleeve which carries the needle. The striker is retained with its spring under com-pression by the retaining shaft. The portion of the shaft which engages the striker sleeve is semi-circular in cross-section, while the upper end has flats formed on it for the at-tachment of the time lever (1). The outer end of the lever is in the form of a toothed segment which is enmeshed with the clockwork escapement housed in a recess in the body. A portion of the lever is cut away to accommodate the safety bolt. The lever is also shaped to engage a projection (11A) on the impact arm (11). The impact arm is pi-voted on the cylindrical portion of the retaining shaft below the timer lever. The strip spring (12) bearing on an extension of the arm tends to make it rotate around the retai-ning of the arm tends to make it rotate around the retaining shaft in a clockwise direc-tion. This rotary movement of the arm is prevented by the projection (10A) on a spring loaded detent (10) housed in a recess in the body. |

|

The base ring is screw-threaded internally to receive the gaine, which is of bakelite and encloses a container of similar design to that of the H.E. unit fitted to some of the Ger-man 1 Kg. incendiary bombs (see Fig. 30). |

| ACTION |

|

When the securing pin of the outer casing is withdrawn the hinged half cylinders and end pieces of the casing are forced to the open position by their springs. The half cylinders acting as a drogue in the air stream of the falling bomb causes the connecting cable to tauten and the end pieces, rotating as the result of their pitch, transmit this turning movement to the safety bolt by means of the connecting cable. After three revolutions the safety bolt is unscrewed sufficiently to un-mask the striker channel and a further three revolutions removes end from the path of the time lever. The collar on the lower end of the safety bolt prevents the bolt being entirely withdrawn from the fuze cap. The subsequent action of the fuze depends upon the position of the setting plug. |

| (a) Set to "AZ" (Percussion Action) |

|

On the withdrawn of the safety bolt from contact with the time lever the striker, under the motive power of its spring, imparts a turning movement to the retaining shaft. The time lever, being rigidly attached to the retaining shaft, turns with the shaft in a clock-wise direction under the control of the clockwork escapement. The impact arm, not being rigidly fixed to the retaining shaft, is held stationary by the projection on the detent. The rotation of the retaining shaft and time lever continues until the timer lever is obstructed by the projection at the end of the impact arm. With the retaining shaft rotated to this position the curved surface of the shaft is almost clear of the striker channel. On impact the detent with its projection sets down, releasing the impact arm, which is then rotated by the action of the strip spring. This movement of the impact arm enables the timer lever and retaining shaft to continue the turning movement and free the striker, which is then driven on to the detonator. This action ion impact is practically instantaneous. |

| (b) Set to "ZEIT" (Time Action) |

|

The action of turning the setting plug to "ZEIT" causes the small pin beneath it to move downwards and depress the spring loaded detent, thus removing the projection on the detent from the path of the impact arm. Under the impulse of the strip spring the impact arm is rotated clear of the path of the time lever. The subsequent action is then as des-cribed in (a) except that the time lever is not obstructed by the projection on the impact arm and completes its rotary movement with the retaining shaft. The striker which elap-ses between the withdrawal of the safety bolt and the firing of the detonator has been found to vary between two and five seconds with different fuzes. |

|

The flash from the detonator passes to the initiator in the gaine by the flash channel (7) and brings about the detonation of the bursting charge by means of the P.E.T.N./wax filling of the gaine. |

| Marking |

|

The outer casing is painted field grey. |